Lab Scale

Benchtop Fermenters and Bioreactors System

In Touch with Biotechnology

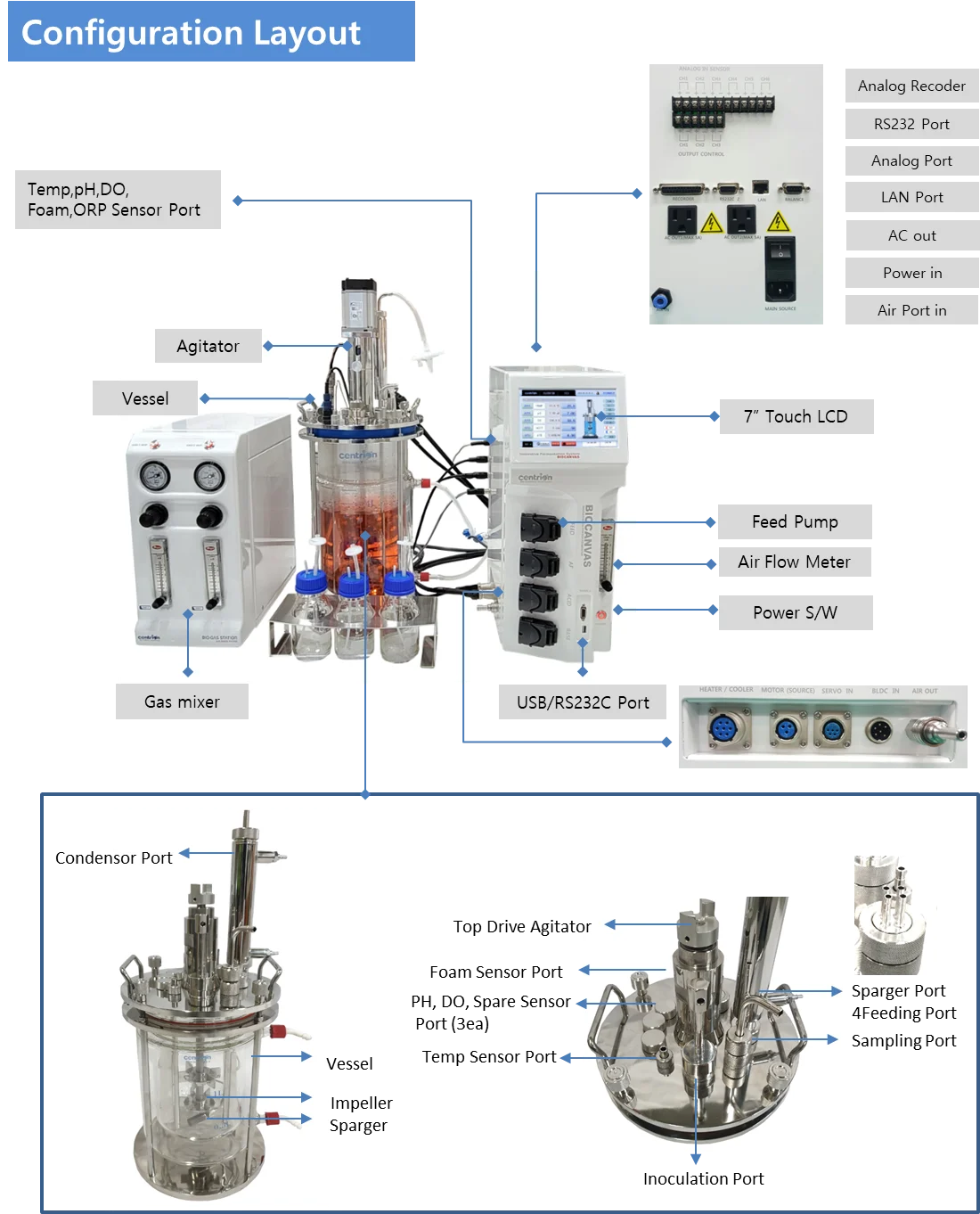

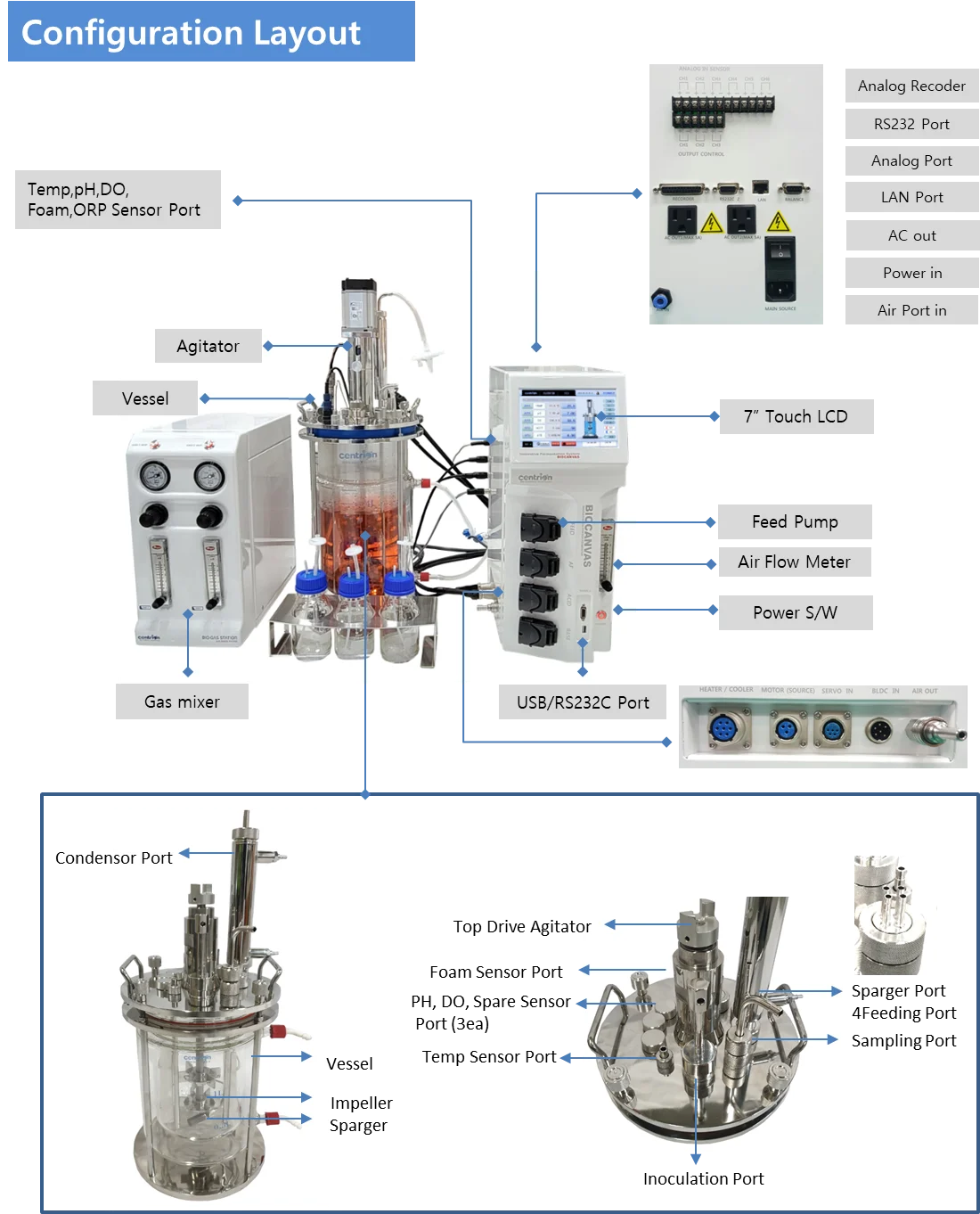

- Design for easy use and maintenance.

- Apply various functions to enable multi-purpose culture experiments

- User-friendly control display configuration.

Main features are:

- Compact design for various culture experiments even in a small space laboratory

- Apply self-diagnosis system that can record and maintain fermentation process, record and control it in real time

- Configured to enable DO Cascade (dissolved oxygen automatic control) so that various culture experiments are possible.

- Control by easily connecting an external device to the fermenter controller (O₂/CO₂ analyzer, gas mixer, scale, level sensor, external pump, analog printer, etc.)

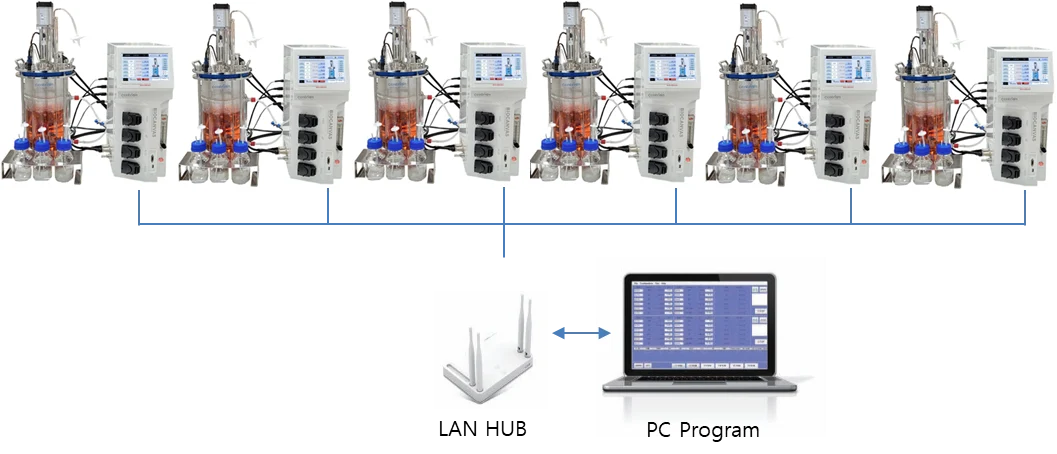

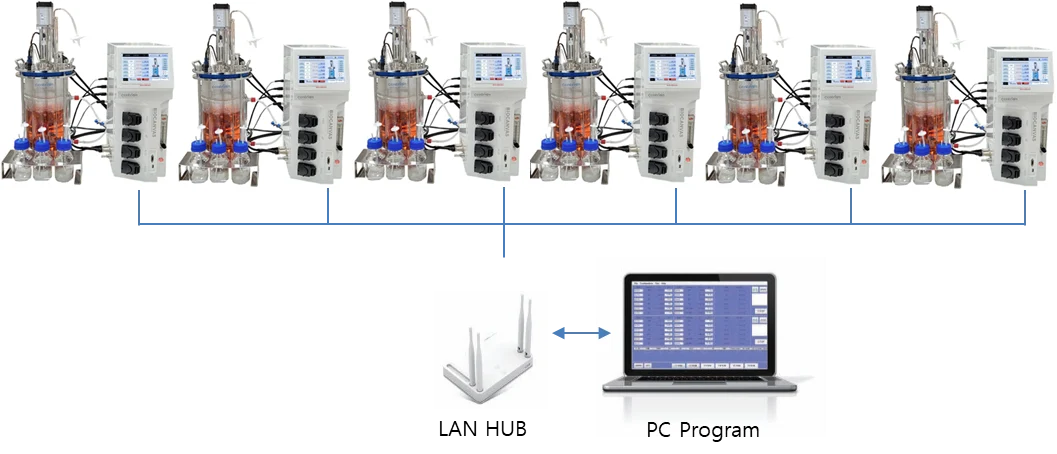

- Manage all data by configuring a multi-channel network through one PC monitor

Available models: BIOCANVAS LF, BIOTWINstation, BIOCANVAS LF Plus

|

Applications

|

Process Modes

|

|

Microbial, insect and mammalian cell culture

|

Batch culture

|

|

Process development

|

Fed-batch culture

|

|

Process optimization

|

Continuous culture

|

|

Process characterization

|

Perfusion culture

|

BIOCANVAS LF and BIOCANVAS LF Plus

Fermenter and Bioreactor Vessel can be customized according to user’s requirements.

Integrated control of 1 to 6 units using a PC control Program

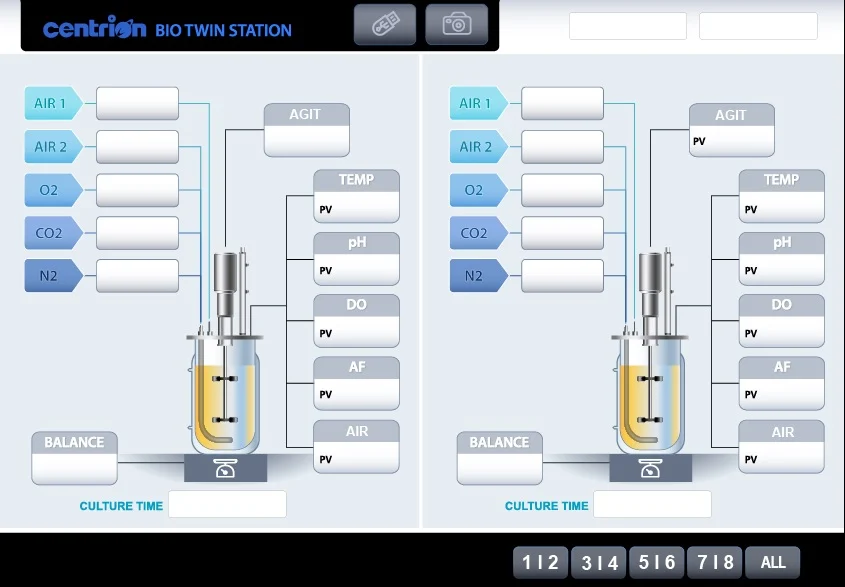

BIOTWINstation

- Single and multi-channel setting to control one or more culture vessels

- Control up to 8CH by one screen

- Secure space by reducing installation space

- Apply 15.6” touch screen applied

- Able to use various vessels ranging from 1L to 13L

Specifications

Standard Specifications

| Vessel Spec | Total Volume(Liter) | 1.5L 3L 5L 7L 10L 13L |

| Working Volume(Liter) | 1 2 3 5 7 10 |

| Material | Borosilicate glass Autoclavable, SUS316L Stainless steel for Top plate and all fittings |

| Etc. | pH, DO, Temp, Foam, Level, Pressure, Addtion Sensor Ports

Exhaust Condenser, Sparger, 4Feeding, Sampling, Inoculation Ports |

| Air Control | Flow rate | 0~10LPM │ 0~20LPM |

| Option | Air Flow Meter / Mass Flow Controller / Mass Flow Manual |

| Sparger | Standard : Ring Sparger / Micro Sparger |

| Inlet Filter | 0.2㎛ Disposable Hydrophobic Filter |

| Agitation Control | Drive | Direct Top Drive Servo Motor 200W~400W,BLDC Motor / Single Mechanical seal

Bottom Magnetic Drive & Servo Motor 200W~400W, BLDC Motor |

| Range | 0~1500rpm |

| Impellers | Rushton Standard With Fermentation / Pitched Blade Standard With Cell Culture

Marine Bladeor Spin Filter Note : Customized impellers areavailable |

| Temp Control | Thermostat system | 0~150℃ ± 0.1℃ / pt100Ω Probe

Heating & Cooling PID Control / Built-in Heat Exchanger / Automatic Cooling Water Valve |

| pH Control | Range / Resolution | 2~14.0 pH of set point, PID control / Gel Type |

| Probe | Electrode Autoclavable, MettlerToledo or Hamilton

(temperature range-0 ~ 140’C, the maximum pressure - 6 bar) |

| Control Mode | Programmable PID Control system |

| DO Control | Range / Resolution | 0~200% or 0~20ppm / 0.1% |

| Probe | Electrode Autoclavable Polarographic or Galvanic Oxygen Sensor - MettlerToledo or Hamilton |

| Control Mode | Programmable PID Control system DO Cascade to Agitation, Mass Flow, Feeding Pump Control

Oxygen enrichment module (optional)

Gas Mixing Station module (optional) |

| ORP Control | Range / Resolution | Measuring range - 1000 ~ -1000 mv. / 1mV |

| Probe | lectrode Autoclavable Redox potential, Oxidation of measurements - MettlerToledo or Hamilton

(Temperature range - 0~140’C, the maximum pressure - 2.5bar) |

| Anti-Foam Control | Range / Sensor | Conductivity 0~300kΩ (Measuring the amount of foam) |

| OD Control | Range / Sensor | Measuring range 0...100EBC 0...100 EBC0...400 FTU (Turbidity measurement) |

| MFM or MFC Control | Range / Sensor | 0~10L/min (Air flow measurement) / Mass Flow Meter / Mass Flow Control |

| Level Sensor Control | Control | Electrode type Hi / Low Vessel Level control |

| Balancer Control | Control | 9,999.99g / RS232C Measured by the amount of weight on the scale output |

| Analog Input & Output | Control | Various sensor are available by utilizing the analog input / output port |

| Analog Recording | Control | It can be the sensor output data value via the analog recording |

Control System Specifications

| Control System | Built-in SCADA System | Built-In SCADA System

- Voltage Specifications : 90~260V 50/60Hz Free Voltage

- Built-in type SMPS Module UL certification.

- PWM frequency control AC Servo Motor, Ac induction Motor, BLDC Motor

And slow down as fast and smooth implementation.

- RS232 x2, RS422 or RS485 communication port

- Analog Input:12points, Analog output : 4points, Analog record:12points

- Temp.,pH, DO Cascade,Foam,ORP,OD,O2,Co2,Agitation,MFC,Pressure, Balancer Control |

| Feed Control Mode | Fed-Batch Culture by DO, pH Inter lock pump Control

6Built-in Feeding Pump(Boxer or Watson-Marlow) External pump 4ea |

| Communication Port | Ethernet | 1PC 1-8 connected to one controller (after completion of standard controller progress)

Data logging, trend graph PC Control : Process Control

(PID, the upper and lower values, programs, cascade, Feed) |

| Record Output | Each sensor can be output by selecting data. D-SUB 25Pin Female Type,

USB Excel file stored separately. |

| USB | Measured data, setup data stored in the USB |

| Pump Module | Pump | 6built - in pumps, two external pump (optional) |

| Motor Type | AC Motor or DC Motor, minimum speed is 10rpm |

| Speed Range | 0~70rpm |

| Resolution | 10rpm |

| Control Mode | Programmable PID Feeding control, Pump can be assigned for Acid, Base, Antifoam, Feed |

| Heating Plate | Range | Up to 90℃ |

| Resolution | 0.1℃ |

| Power Source | 100-120V ~ 50/60Hz or 210-230V ~ 50/60Hz With electrical safety cult off switch |